The Telematics Journey

Telematics are becoming an indispensable tool for fleet managers looking to maximize equipment uptime. These solutions always promise to make the end user’s job easier but getting to real, business altering insights is not plug and play – it’s complex. At Fleet Intelligence, we see implementing a telematics solution as an 8-step journey, and we believe it’s important for equipment managers to fully understand where they are on this journey, the challenges they face at each step, and the solutions they should expect from any fleet management solution.

The Telematics Journey

Telematics are becoming an indispensable tool for fleet managers looking to maximize equipment uptime. These solutions always promise to make the end user’s job easier but getting to real, business altering insights is not plug and play – it’s complex. At Fleet Intelligence, we see implementing a telematics solution as an 8-step journey, and we believe it’s important for equipment managers to fully understand where they are on this journey, the challenges they face at each step, and the solutions they should expect from any fleet management solution.

Schedule A Demo

All-In-One

Asset Protection

Preventive Maintenance

DTC /

Oil Scan

Utilization Efficiencies

Integration

Machine Life-Cycle Management

Customer Centric Partner Portal

Schedule A Demo

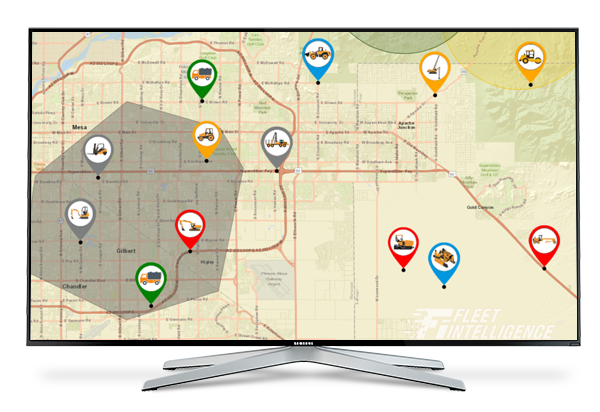

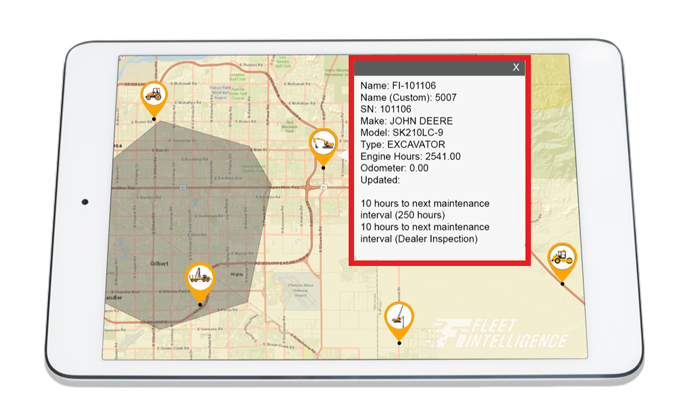

See all your equipment on one live map

The most obvious and eye-opening benefit of a telematics solution is being able to see all equipment and assets on one live map. Managing a fleet without this basic feature can make knowing where assets are a challenge for even the most experienced asset manager.

How do you know if you’re getting the most out of being able to see everything on one map? If any of the following activities are a common occurrence, you’re likely in the All-in-One stage of the Telematics Journey:

Fleet Intelligence is designed to give equipment and asset managers the ability to see their entire mixed fleet on one live map. Having this insight makes it easier to manage, and scale the management of, a heavy equipment or OTR fleet. And it gives the managers the ability to focus not on where machines are, but how they’re used, which is crucial to generating greater efficiency and decreasing costs.

See how your mixed fleet would look on one live map by scheduling a demo with a Fleet Intelligence rep

Protect assets, reduce risk, and manage costs

Even if you’re able to see your assets on one map, wondering if they’re protected can keep you up at night. Stolen equipment is a real problem. The National Equipment Register (NER) estimates between $300 million to $1 billion of construction equipment is stolen annually. Jobsite theft can crush a job’s profitability through replacement or rental costs, lost productivity, schedule delays, and increases in insurance premiums. We recommend reading Cal/Amp’s 2016 Study on Equipment Theft for a detailed analysis of the scope of this problem.

If you notice any of the following signs, you might be at this point in the Telematics Journey:

A fleet management solution should have built-in tools which protect your fleet. With Fleet Intelligence, equipment managers have access to the protection features:

24/7 Asset Visibility – see where your equipment is at all times

Custom Geofences with Notifications – managers can draw geofences around their jobsite and receive notifications if any asset is operated outside of the perimeter

Custom Curfews and Notifications – set time ranges for machine operation and receive notifications if equipment is used outside of curfew ranges

Tamper Notifications – lets managers know when telematics devices have been altered or removed, so they can react quickly to potential theft or misuse

Technology can make managers confident that equipment is protected. The big challenge of being in this stage is that managers are still concerned with where their equipment is, and they aren’t able to laser focus on the real driver of efficiency: how machines are being used.

Schedule a demo to see how Fleet Intelligence protects your equipment

Increase uptime by automating maintenance

Step three is where equipment managers make noticeable improvements to fleet efficiency and uptime – because they’re now focused on how machines perform instead of where they’re located. Once machines have been secured, the common desire is to make sure they are properly maintained to avoid problems, failures, and breakdowns. Too often maintenance records and reports are recorded by hand or in a spreadsheet – siloing actionable data from the rest of the organization. This increases the amount of time required for reactive maintenance and results in machine downtime.

Using telematics to manage preventative maintenance and repairs is the easiest and fastest way for an equipment manager to increase uptime and efficiency. Fleet Intelligence helps provide a quick win for equipment managers with the following features:

Custom maintenance schedules for each asset

Automated maintenance tracking

Upcoming maintenance alerts

See how Fleet Intelligence can improve fleet efficiency through preventative maintenance

Schedule a demo to learn more about how FI Tracker can improve your bottom line.

888-658-6562